- Description

- Inquiry

- Working environment

■ Environment temperature: -50 ~ 45℃

■ Relative humidity: 20 ~ 95%

■ The site does not allow the medium with explosive danger, and the surrounding medium should not contain corrosion metal and destroying insulation gas and conductive medium.

- Equipment composition

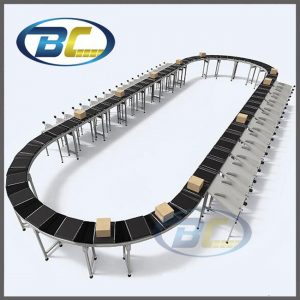

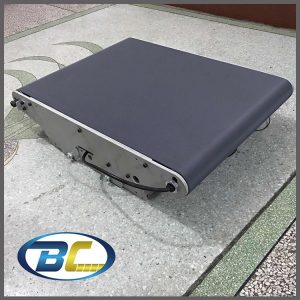

The modular belt sorter is composed of plastic belt, motor and control cabinet. The core part is the plastic modular roller belt. The modular belt supplies the straight driving force. The rollers supplies the switching force for left and right sorting so as to achieve two-way diverting, so the goods can be sorted.

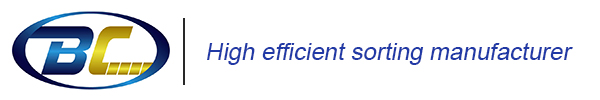

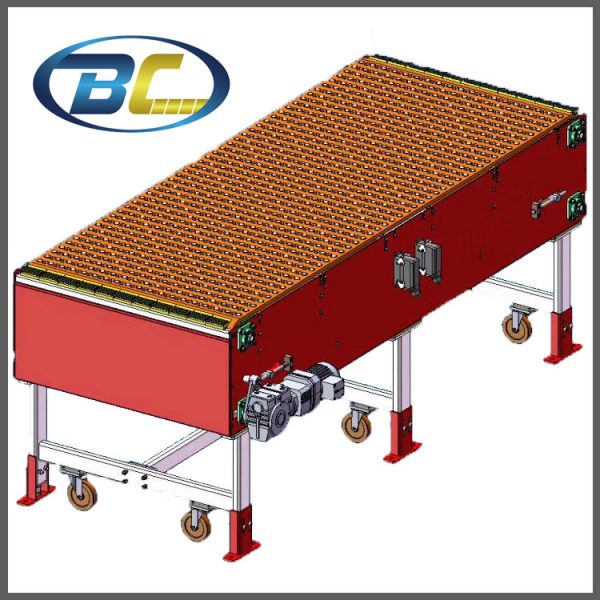

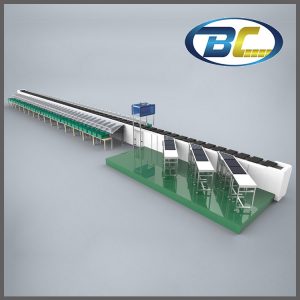

General view

1)Modular roller belt: supply driven force for the parcel moving.

2)Carbon steel plate: the mechanical structure of the equipment.

3)Electrical connector:connect cabinet and servo sorting belt, convenient for disassembling and maintenance.

4)Maintenance window: through the window can observe the internal structure, convenient for maintenance.

5)Motor: driven force

6)Rollers: increase the smooth moving.

3. Technical data and parameter

| Item | Content | Data | Remark |

| 1 | Dimension | 1150mm(bilateral) | customized |

| 2 | Height | Above 500mm | customized |

| 3 | Power supply | AC380V | |

| 4 | Max. speed | 1.2m/s | |

| 5 | Theoretically sorting efficiency | 4800PCS/H | |

| 6 | Sorting range | Cartons, parcels, strong package with flat bottom | |

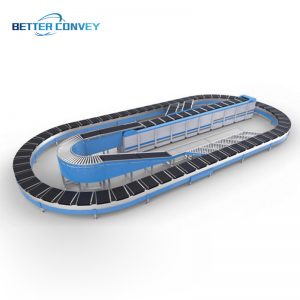

4. Application

This equipment is used for the occasions of sorting, diverting and conveying together. Can be used with conveyors, scanning and weighing and WCS software.

5. Installation and commissioning

All parts are driven by connecting rods, easy to assemble, interchangeable and universal.

The installation and commissioning of the equipment are required to operate by our professional and technical personnel or the operaters authorized by our company. Equipment must be installed with matched mounting brackets. Forklift or crane will be used to move the equipments to place it in the designated location.Make sure the equipment aligns and all fasteners are installed firmly.

After the main structure of the equipment is installed, then start to install the electrical control components. All the equipment has an independent control cabinet, connected with the main equipment by communication bus standard and fast joints to ensure the fast and accurate installation.

After finishing installation, start to connect the software and test. It can be used with independent system or with other systems.

6. Maintenance

Mechanical part: Routine inspection of the drive shaft, make sure there is enough oil in the bearing. It is necessary to clean up the surface dust and dirt regularly to ensure the smooth operation of the mechanism.

Electric part: Daily inspection of electrical components in the control cabinet to prevent the leakage of mouse biting or water soaking.